The incorporation of nanoparticles into polymers constitutes a powerful strategy for enhancing their mechanical properties and for introducing new optical, electrical, and magnetic functionalities into the polymers. While many traditional applications of polymer-nanoparticle composites (PNCs) prefer the nanoparticles to remain dispersed in the polymer matrix, some of the newer, sophisticated applications (e.g. in plasmonics, optics, and energy storage) require the particles to be assembled into specific arrangements or higher order structures (Fig. 1). However, achieving precise, unique, and complex particle assemblies remains a challenging task. In our group, we use a combination of theory, simulations, and machine learning to explore new strategies for self-assembling particles into unique non close-packed arrangements and elucidate the underlying mechanisms, energetics, and dynamics of assembly.

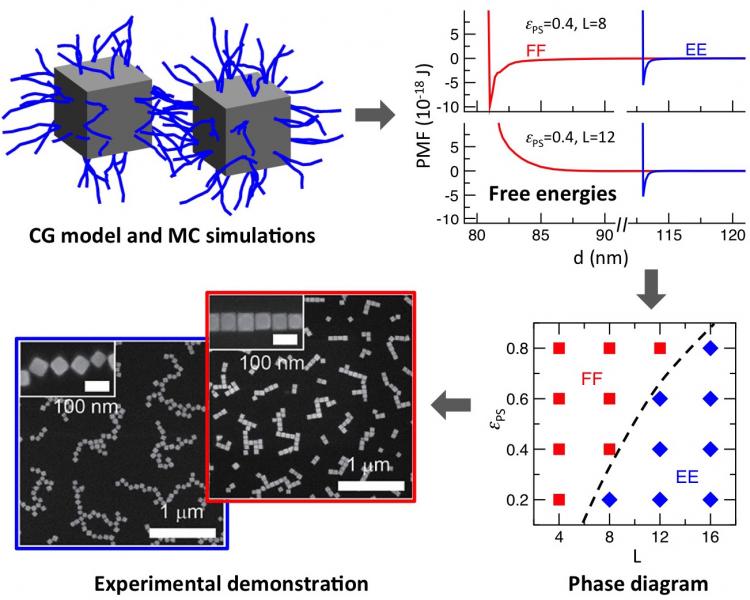

Our main focus has been on understanding how shaped, polymer-grafted nanoparticles interact with each other and how one could manipulate such interactions to make the particles assemble into higher-order structures relevant to plasmonics. A key feature of this work is the use of coarse-grained models and advanced simulation methods to compute free energy landscapes and phase diagrams relevant to assembly. Our efforts have led to a remarkably simple entropy-based strategy, involving changes in the length of grafted chains, for tuning the interparticle orientation of nanocubes between face-to-face and edge-to-edge configurations. Even more remarkably, this concept enabled our collaborators to develop a simple experimental approach for fabricating tunable plasmonic hotspots over macroscopic areas (Fig. 2). Currently, we are developing analytical scaling relations for the free energy of interaction between polymer-grafted faceted particles to speed up the construction of phase diagrams.

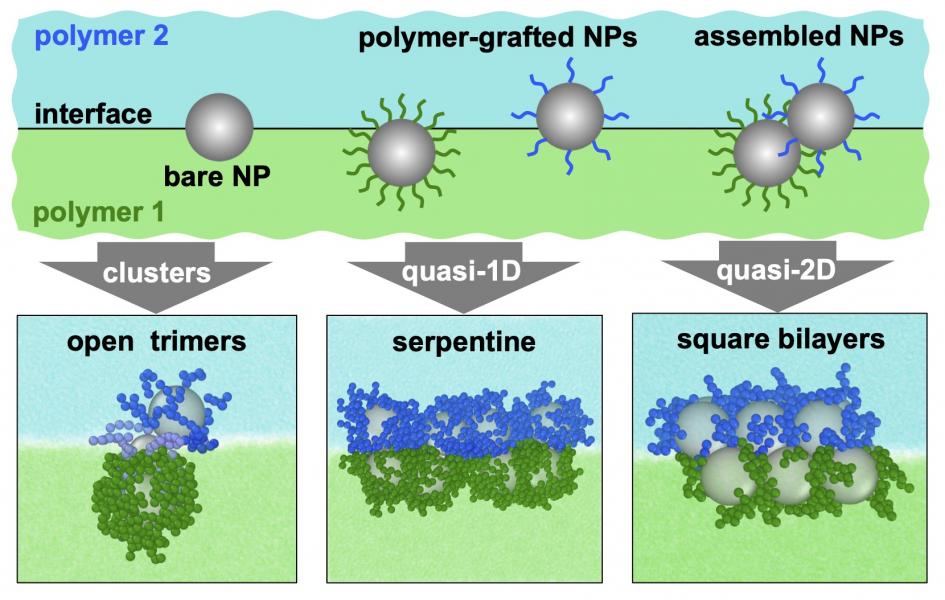

More recently, we developed a novel strategy for assembling polymer-grafted spherical nanoparticles into unique anisotropic clusters and phases. The approach takes advantage of the surface tension between two mutually immiscible polymers forming a bilayer and differences in the compatibility of the two polymer layers with polymer grafts on particles to trap them within two-dimensional planes parallel to the interface (Fig. 3). By trapping multiple interacting particles at distinct planes, we were able to assemble nanoparticles into unique tunable clusters as well as anisotropic 1D and 2D phases. We are currently using theoretical models of interparticle and interfacial interactions coupled with powerful MC-based optimization algorithms to explore the full breadth of nanoparticle phases achievable using this new approach. Other ongoing efforts include exploiting interfacial and multibody interactions to create reconfigurable phases of shaped nanoparticles.

We are also excited about the prospect of using machine-learning (ML) strategies to model multibody effects in polymer-grafted systems. For instance, we recently introduced a new ML framework based on permutationally invariant polynomials to develop an many-body effective potentials for polymer-grafted nanoparticles suspended in a polymer melt (Fig. 4). Molecular dynamics simulations carried out using this many-body potential could not only reproduce previously known assembled phases such as 1D strings and 2D hexagonal sheets, which generally cannot be achieved using isotropic two-body potentials, but can also help discover novel phases such as networks, clusters, and gels. We further used the potential to demonstrate how these assembly morphologies intrinsically arises from a competition between two- and three-body interactions. Such potentials will allow researchers to rapidly, yet accurately, predict the assembly behavior of ligand-functionalized colloidal systems without the need to simulate the polymeric medium or the grafted polymer chains.

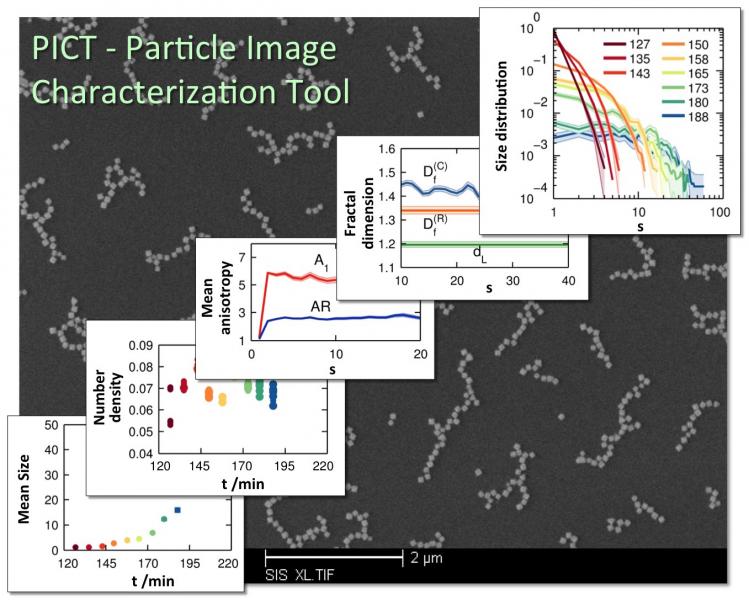

We have also spent considerable effort in analyzing experimental images of nanoparticles assembling in polymer films. We developed an automated quantitative image analysis tool that allows researchers to analyze electron microscopy images of nanocomposites and obtain a range of structural properties of nanoparticle clusters as they assemble into higher-order structures (Fig. 5). The first version of this software, named particle image characterization tool or PICT, is available for download from the MATLAB Exchange Server. Simultaneously, we also developed a kinetic lattice Monte Carlo model of nanoparticle assembly that allowed us to recover key dynamic parameters of assembly from the analysis of static, disjointed microscopy images of the nanocomposites. We are now extending both these efforts to multicomponent particle systems, which are expected to yield more diverse assembly morphologies.

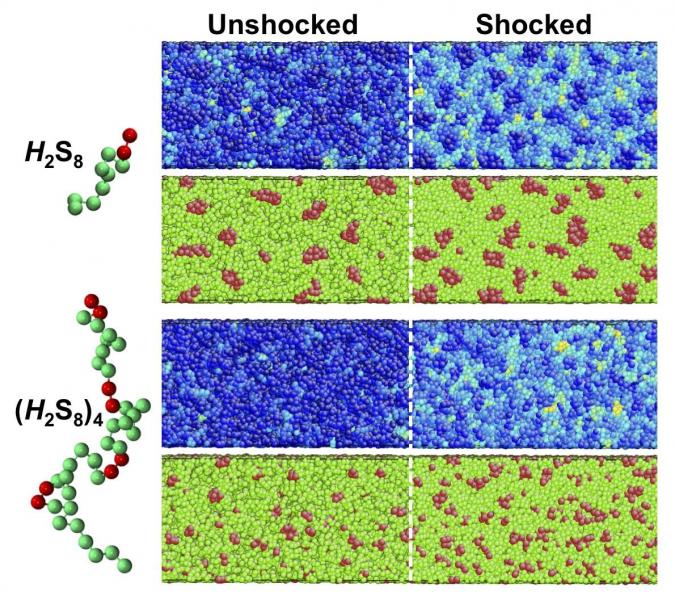

In recent past, we were involved in a project concerning the development of advanced polymer coatings for shock mitigation. Specifically, experiments have shown that incorporation of silica nanoparticles into polyurea—current gold standard for such applications—significantly improved its dissipative properties. A major focus of our work was on elucidating the role of polyurea microstructure and the added nanoparticles, especially the polymer grafts, on the viscoelastic behavior and shock response of the resulting polyurea nanocomposites (Fig. 6). Our work also led to the development of accurate coarse-grained models of polyurea that reproduce not only its microstructure, but also its stress relaxation spectrum.

Another recently completed project is on understanding how mechanical properties of organic semiconductors depend on their molecular architecture with the ultimate aim of enhancing their mechanical compliance and durability. This work was done in close collaboration with Dr. Darren Lipomi (UCSD). Our initial studies have examined the ability of all- atom and coarse-grained molecular dynamics simulations to predict morphological, thermophysical, and mechanical properties of various conjugated semiconducting polymers, including recently developed donor-acceptor polymers (Fig. 7). Ongoing work is focusing on developing more transferable and accurate CG models of these complex polymers.